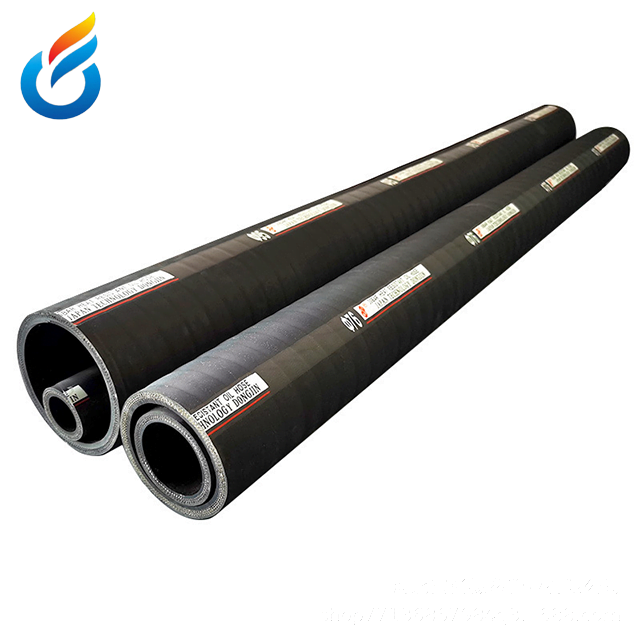

Structure of Large Diameter Low Pressure Wear-Resistant Rubber Hose

A large diameter low pressure wear-resistant rubber hose consists of several key components, each serving specific functions to ensure the hose’s wear resistance, pressure adaptability, and overall performance.

1. Inner Layer (Lining)

Material: Typically made of wear-resistant rubber (such as natural rubber, nitrile rubber, or polyurethane).

Function: Directly contacts the conveyed medium, providing excellent wear resistance and protecting against corrosion and abrasion.

2. Reinforcement Layer

Material: High-strength fiber fabrics (such as polyester, nylon), metal wire mesh, or braiding.

Function: Increases the mechanical strength and pressure-bearing capacity of the hose, preventing rupture or deformation during use.

3. Intermediate Rubber Layer

Material: Usually similar rubber material as the inner layer.

Function: Effectively bonds the inner layer and the reinforcement layer, ensuring adhesion and the stability of the overall structure.

4. Outer Layer

Material: Rubber with strong weather resistance (such as neoprene, EPDM rubber).

Function: Protects the internal structure of the hose from external environmental impacts like sunlight, oxidation, and chemicals, thus extending the hose’s service life.

5. Fittings (Optional)

Material: Typically metal (such as steel, stainless steel) or hard plastic.

Function: Facilitates the connection and installation of the hose, providing reliable sealing performance to prevent medium leakage.

6. Lining Layer (Optional)

Material: Special rubber or plastic material.

Function: Used in specific applications to further enhance wear resistance or provide additional chemical resistance.

These layers work together to form the complete structure of a large diameter low pressure wear-resistant rubber hose, ensuring excellent wear resistance, flexibility, and durability in various applications.