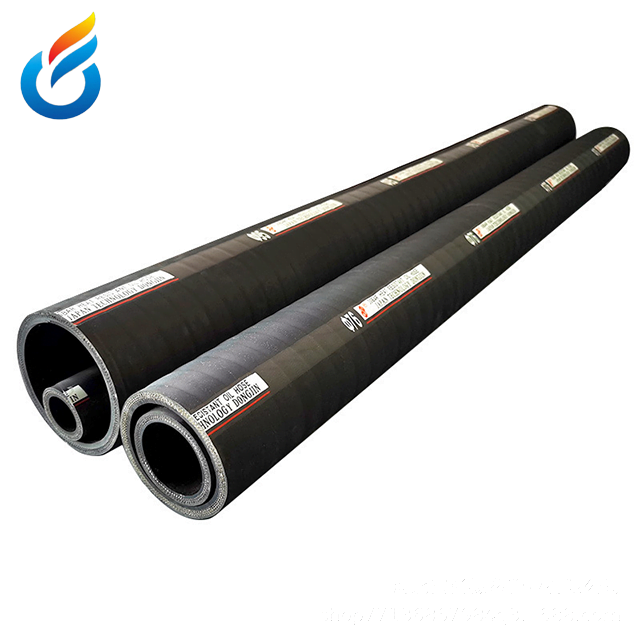

Hydraulic Hoses: Applications, Types, and Maintenance Guide

Hydraulic hoses play a crucial role in modern industrial and mechanical equipment. They are widely used in various hydraulic systems, providing efficient and reliable fluid transmission solutions. This article will explore the applications, types, and maintenance points of hydraulic hoses.

Applications of Hydraulic Hoses

Hydraulic hoses are widely used in the following fields:

1、Construction Machinery: Hydraulic hoses are used in excavators, loaders, and bulldozers to transmit hydraulic oil and drive hydraulic cylinders and motors.

2、Agricultural Equipment: In agricultural machinery such as tractors, combines, and sprayers, hydraulic hoses are used to control and drive various hydraulic devices.

3、Industrial Manufacturing: Hydraulic hoses are used in hydraulic presses, injection molding machines, and automated production lines to achieve high-pressure fluid transmission and control.

4、Aerospace: Hydraulic hoses ensure precise fluid control in the hydraulic systems of aircraft and spacecraft, ensuring flight safety.

Types of Hydraulic Hoses

Hydraulic hoses can be classified into the following types based on the application scenario and working pressure:

1、Low-Pressure Hydraulic Hoses: Suitable for low-pressure applications, such as return lines and drain lines.

2、Medium-Pressure Hydraulic Hoses: Widely used in medium-pressure hydraulic systems for transmission and control circuits.

3、High-Pressure Hydraulic Hoses: Suitable for high-pressure environments, such as driving circuits for hydraulic cylinders and motors.

4、Ultra-High-Pressure Hydraulic Hoses: Used for special applications with ultra-high pressure, such as hydraulic testing equipment and special engineering machinery.

Maintenance of Hydraulic Hoses

Regular maintenance is crucial to ensure the long-term reliable operation of hydraulic hoses. Here are some key maintenance points:

1、Regular Inspection: Regularly inspect the appearance of hydraulic hoses for wear, cracks, or oil leakage. If problems are found, replace them promptly.

2、Keep Clean: Ensure the cleanliness of hydraulic hoses and their connection parts to prevent impurities from entering the hydraulic system and causing blockages or damage.

3、Proper Installation: The installation of hydraulic hoses should comply with standards, avoiding excessive bending and twisting to prevent damage due to mechanical stress.

4、Temperature Control: Control the operating temperature of the hydraulic system within the temperature range of the hydraulic hose to avoid damage due to excessive or insufficient temperatures.

Conclusion

Hydraulic hoses are indispensable in modern industrial and mechanical equipment. By choosing the appropriate type of hydraulic hose and performing regular maintenance, the reliability and service life of hydraulic systems can be effectively improved. I hope this article provides a deeper understanding of the applications, types, and maintenance of hydraulic hoses and can serve as a reference and help for your work.

If you have more questions or needs regarding hydraulic hoses, feel free to contact our professional team, and we will be happy to assist you.